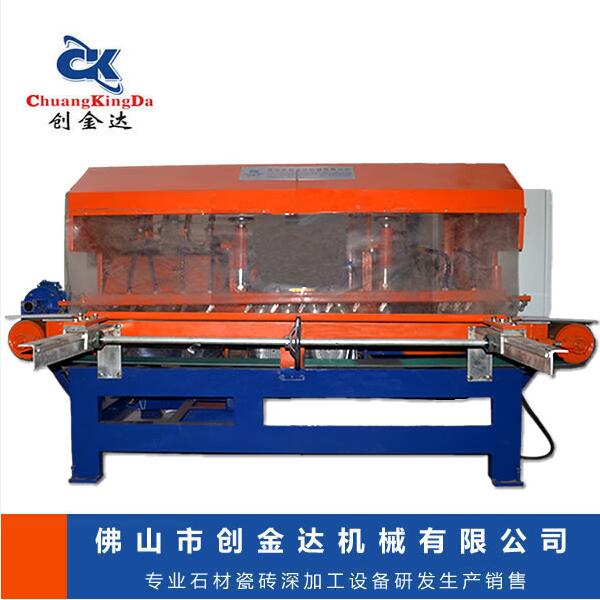

Ball mill

Product introduce:

Ball mill machine is ceramic industry grinding machine, suitable for wet ball mill stone, quartz, clay material, ball grinding fineness can through the screen.

Product features:

Convenient installation, safe reliable, load materials time is short, alleviate worker workload intensity. high grinding degree, s***e material, reduce cost, improve product quality, high efficiency and energy s***ing, is the main ceramics factory raw material processing workshop necessary equipment.

Products use principle:

Ball mill is mainly composed of barrel, main bearing, reinforced concrete support, tran***ission parts and so on. barrel is a including shaft head,seal head, the welding of tube body combination as a whole. On the cylinder is equipped with two feeding port and discharging let with and into the hole, is ***ailable with lining.

Cylinder operation points, main drive and auxiliary tran***ission, main drive is level by the end of the main motor reducer belt drive, level at the end of the conveyor belt is composed of triangle, triangle, a package on the pulley groove pit, make a bag on the tube surface.

Auxiliary tran***ission is by auxiliary motor reducer and level at the end of the belt drive.

Main tran***ission tube body material grinding

|

Model |

feeding |

Cylinder round speed (r/min) |

Main motor(kw) |

Lining texture |

|

0.1T Ball Mill |

0.1 |

55 |

1.5 |

|

|

0.2T Ball Mill |

0.2 |

45 |

3 |

|

|

0.35T Ball Mill |

0.35 |

38 |

4 |

|

|

0.5T Ball Mill |

0.5 |

31.7 |

5.5 |

|

|

1T Ball Mill |

1 |

31 |

15 |

|

|

1.5T Ball Mill |

1.5 |

23 |

18.5 |

|

|

2T Ball Mill |

2 |

19 |

22 |

|

|

3T Ball Mill |

3 |

18.7 |

37 |

|

|

5T Ball Mill |

5 |

27 |

55 |

|

|

5T Ball Mill G Type |

5 |

19.3 |

45 |

|

|

8T Ball Mill |

8 |

14.88 |

75 |

|

|

14T Ball Mill |

14 |

13.57 |

75 |

Ceramic, silica, rubber, metal (supporting power according to the using and the liner material grinding materials of different will differ) |

|

18T Ball Mill |

18 |

13.87 |

90 |

|

|

23T Ball Mill |

23 |

13.3 |

90 |

|

|

30T Ball Mill |

30 |

12.5 |

110 |

|

|

36T Ball Mill |

36 |

11.8 |

132 |

|

|

38T Ball Mill |

38 |

11.8 |

132 |

|

|

40T Ball Mill |

40 |

11.8 |

132 |

|

|

50T Ball Mill |

50 |

11.5 |

160 |

|

|

60T Ball Mill |

60 |

9.92 |

200 |

|

|

80T Ball Mill |

80 |

9.92 |

250 |

|

|

100T Ball Mill |

100 |

10 |

25 |

Contact Us

CHUANGKINGDA MACHINERY CO., LTD.

***on Zhang

Phone Id: +8618022295346 (whatsapp, line, wechat, skype)

***: 1541384006

website: http://chuangkingda.en.